NEXT

Introduction

In earlier days, switches and fuses were placed in series to control (ON or OFF) the various circuits under both normal and abnormal (faulty) conditions. But the problem arises when fuse blows out it takes a considerable time to replace it and also not able to operate successfully under high voltage or have faults. Which affects the continuity of supply and reduced reliability of power system. To avoid this problem a device is used in modern days known as circuit breakers. Modern circuit breakers are able to operates at low voltages as well as very high voltage and also able to carry large current.

Therefore, circuit breaker is a very important power system device design to open or close the various electric circuits under both normal and faulty condition it can operate manually under normally conditions and automatically under faulty conditions.

Function of circuit breaker

A circuit breaker has ability to operate manually as well as automatically under all condition viz no load, full load and faulty conditions.

Under normal conditions, the circuit breakers are able to operate manually. In this way, circuit breaker ensure the safety of workers while maintenance of power system.

Under faulty conditions, the circuit breakers are able to operate automatically. The circuit breaker disconnects the faulty parts from the power system. In this way, circuit breaker protect the system from damaged and ensure continuity of power supply.

Although, the basic function of circuit breaker is to open or energized the power system when protective really detect any fault.

Working principle of circuit breaker?

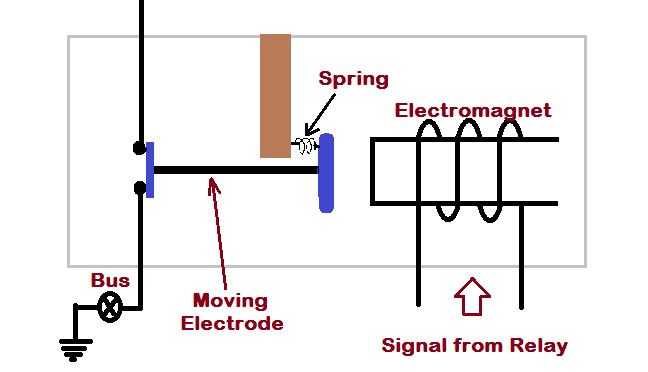

A circuit breaker consists of two electrodes, one is fixed and another is moving. Under normal operating condition, these two electrodes are in contact with each other and circuit is closed. The circuit will not open automatically until and unless the system become faulty. The contacts can be opened manually or by by remote control whenever desired.

When a fault occur on any part of power system, the trip coil of circuit breaker get energized and the moving electrode is pulled by electromagnet and thus opening the circuits.

The construction and design of circuit breaker becomes more complicated for high voltage power system and heavy faults.

When the contacts of a circuit breaker are separated under faulty conditions, and arc is structed between them. The current is thus able to continuous until the discharge ceases. The production of arc preset two disadvantages:

Firstly, it delay the current interruption process and secondly, it may generate heavy heat which cause damage to system or circuit breaker itself. Therefore, the main problem in a circuit breaker is to extinguish the arc within the shortest possible time.

Classification of circuit breaker

There are several ways of classifying the circuit breaker. Generally, circuit breaker are classified on the basis of medium used for arc extinction.

On the basis of medium used for arc extinction, the circuit breaker may be classified as

1. Oil circuit breaker

2. Air circuit breaker

3. SF6 circuit breaker

4. Air blast circuit breaker

5. Vacuum circuit breaker

On the basis their services, the circuit breaker may be classified as

1. Outdoor circuit breaker

2. Indoor circuit breaker

On the basis of operating mechanism of circuit breaker, they are classified as

1. Pneumatic circuit breaker

2. Hydraulic circuit breaker

3. Spring operated circuit breaker

On the basis of voltage level, circuit breaker classified as

1. Low voltage circuit breaker (less then 1000V)

2. Medium voltage circuit breaker (1kV to 72 kV).

3. High Voltage circuit breaker (above 72 kV).

Advantages of circuit breakers

1. It operates at high voltage as compared to fuse.

2. It protect the higher voltage system from damaged.

3. Circuit breaker can operate its manually which can not done in fuse.

4. No need to replace the circuit breaker after fault.

5. It increases the reliability of power system.

Testing of circuit breakers

Testing of circuit breakers can be classified into two main groups i.e. type test and routine test. Although, the testing of circuit breaker is not easy as testing of other electrical equipment like transformers or machines because the short circuit current are very large.

Types tests

These tests are conducted on first few prototype circuit breakers of each type for the purpose of providing the capability is and confirming the return characteristics of the circuit breaker of that designed. Type tests can be classified as mechanical performance test, thermal tests, dielectric insulation tests and short circuits tests in order to check making capacity, breaking capacity, short time braking current and operating duty.

1. Mechanical tests: These are mechanical endurance type tests involves repeated opening and closing of the circuit breaker.

2. Thermal tests: As its name suggests, these tests are conducted to check the thermal behaviour of the circuit breaker.

3. Dielectric tests: These tests are carried out to check power frequency and impulse voltage withstand capacity.

4. Short circuit tests: Circuit breakers are subjected to sudden short circuits test laboratories and oscillograms are taken to know the behaviour of the circuit breakers at the time of switching-in, during contact breaking and after arc extinction.

Routine tests

Once type tests are conducted and a particular design is found to be satisfactory the product it becomes prototype and largest number of circuit breakers of similar designed are manufactured. However, each and every circuit breaker is still so subjected to a few more test before commissioning. These tests are called routine tests.

Routine tests can be classified as

– Power frequency voltage tests

– Millivolt drop test and

– Operating tests.